I've just completed the files to laser-cut the frames and parts for the Rip Tide RC Vintage Marblehead sailboat.

There are two options: One with the original 13" draft fin, and one with the extended 16" draft fin. Otherwise the boats are exactly the same.

NOTE: BOTH VERSIONS STILL PLACE THE BOAT IN THE "HIGH FLYER" CATEGORY! The shorter fin is still too deep for the "Traditional" class, and the rudder is spade not skeg which also disqualifies it for "Traditional".

The fin depth is a matter of which you think would work with the rig that you'll add to the boat. Some people suggested that I keep a version with a shorter fin, so I offer it here. Personally I'd go with the deeper 16" fin if only because it looks better!

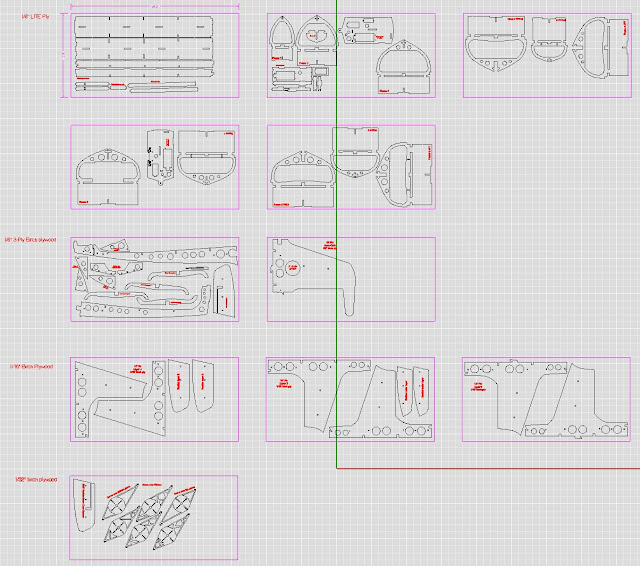

Here's what you get with the 13" draft fin:

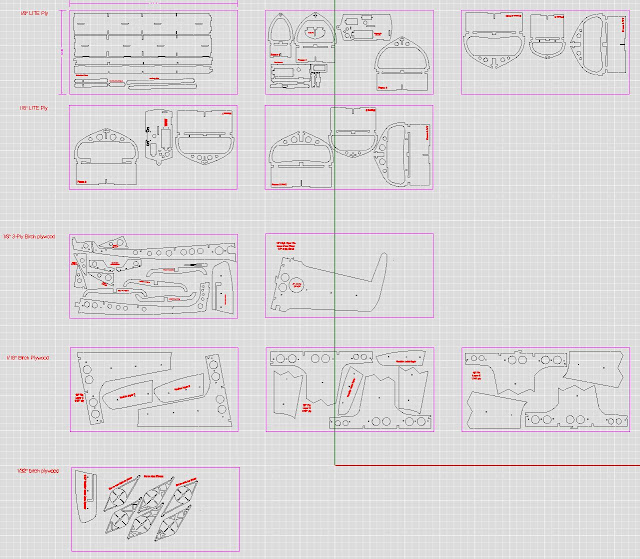

And here's what you get with the 16" draft fin:

Yes, they are exactly the same except for the fin parts. If you look carefully, you'll notice that parts that make the fins are different, but everything else is the same.

And yes, the top parts of the fins are exactly the same too so that they will fit onto the rest of the identical keel structure.

And NO, the fins are NOT removable or interchangeable. You must commit to one of the two fins, and it will then be permanently built into the boat. And again, both are "High Flyer" boats.

NOTE: As of 12/17/2017 I have NOT built either version of these frames. If you are interested in building one of these two versions, please let me know. I can set up the cutting with National Balsa and you can then order the frames from them. But please understand, you would be doing the very first build using these frames. While I've very carefully made the 3D model, and have inspected it as closely as I can, I cannot fully guarantee perfect fits on all parts. You may have to make some modifications on your own. Please report those back to me. Yes, you'd be taking a bit of a risk, but if you're considering building one of these, then you probably already have some skills with building RC boats and can punt when needed. I'd also like to find someone who will commit to actually building one relatively soon.

Also NOTE that any expenses are yours. I can't afford to purchase the frames for you. The only help I can offer would be a free copy of my "Vintage Marblehead Construction Manual" in PDF format for the first two builders who buy the frames from National Balsa. Otherwise you're on your own. So I'd really like to find someone experienced to try the first build.

Aloha!!

There are two options: One with the original 13" draft fin, and one with the extended 16" draft fin. Otherwise the boats are exactly the same.

NOTE: BOTH VERSIONS STILL PLACE THE BOAT IN THE "HIGH FLYER" CATEGORY! The shorter fin is still too deep for the "Traditional" class, and the rudder is spade not skeg which also disqualifies it for "Traditional".

The fin depth is a matter of which you think would work with the rig that you'll add to the boat. Some people suggested that I keep a version with a shorter fin, so I offer it here. Personally I'd go with the deeper 16" fin if only because it looks better!

Here's what you get with the 13" draft fin:

And here's what you get with the 16" draft fin:

Yes, they are exactly the same except for the fin parts. If you look carefully, you'll notice that parts that make the fins are different, but everything else is the same.

And yes, the top parts of the fins are exactly the same too so that they will fit onto the rest of the identical keel structure.

And NO, the fins are NOT removable or interchangeable. You must commit to one of the two fins, and it will then be permanently built into the boat. And again, both are "High Flyer" boats.

NOTE: As of 12/17/2017 I have NOT built either version of these frames. If you are interested in building one of these two versions, please let me know. I can set up the cutting with National Balsa and you can then order the frames from them. But please understand, you would be doing the very first build using these frames. While I've very carefully made the 3D model, and have inspected it as closely as I can, I cannot fully guarantee perfect fits on all parts. You may have to make some modifications on your own. Please report those back to me. Yes, you'd be taking a bit of a risk, but if you're considering building one of these, then you probably already have some skills with building RC boats and can punt when needed. I'd also like to find someone who will commit to actually building one relatively soon.

Also NOTE that any expenses are yours. I can't afford to purchase the frames for you. The only help I can offer would be a free copy of my "Vintage Marblehead Construction Manual" in PDF format for the first two builders who buy the frames from National Balsa. Otherwise you're on your own. So I'd really like to find someone experienced to try the first build.

Aloha!!

What has been the response on this? I am considering building Rip Tide as a winter project.

ReplyDeleteHello Unknown, :P

ReplyDeleteI've had four or five people inquire about them, and only one that I know has purchased the frames. Others may have but haven't let me know.

If you wish, you can email me and we can chat more about it and how to get started!

Steve