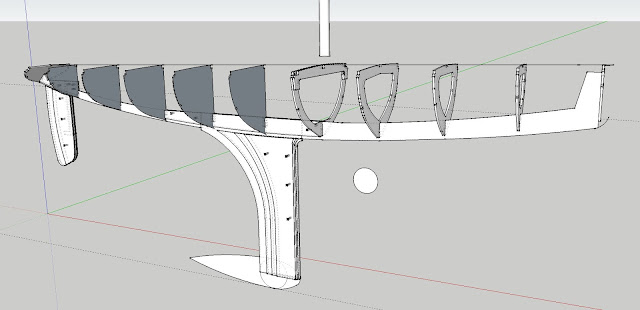

Have been working on the Sun Wind Radio Control sailboat 3D model today. Got the keel parts and the rudder worked out.

The rudder looks large, but the concept is that you laminate those parts together and then sand the hell out of it until you get down to the shape you want. It won't be as thick or as deep fore and aft as it looks now. Although a larger rudder would be good, so you shouldn't sand it entirely away.

Today's progress...

The circle is a 2" diameter cutout that you can use to gauge the garboard hollow. The Vintage Marblehead rules state that: "Garboards: Garboards shall be hollow, with not less than a one inch radius in the area of the keel fin. This may be checked by use of a disk 2 inches in diameter, fitted to the garboard at a midship section." So... that is what that disk is for.

In the old days they used to carve a very massive (relative to the size of the hull) keel out of solid wood. Then, when the boat was planked, it was the style to have that heavy keel project downward from the canoe shape of the hull. The fin was fitted through a slot in that large piece of wood. That keel piece would be rounded to blend from the hull down to the fin. They actually made a rule that requires this "garboard". It must be at least 1" radius. So instead of trying to carve and shape a large and heavy piece of wood, I'll just filet in a bunch of thickened epoxy and round it over with the disk. It will clean up very easily and will be incredibly strong. If I use the micro-balloons to thicken the epoxy then it shouldn't be too heavy either.

Aloha!

The rudder looks large, but the concept is that you laminate those parts together and then sand the hell out of it until you get down to the shape you want. It won't be as thick or as deep fore and aft as it looks now. Although a larger rudder would be good, so you shouldn't sand it entirely away.

Today's progress...

The circle is a 2" diameter cutout that you can use to gauge the garboard hollow. The Vintage Marblehead rules state that: "Garboards: Garboards shall be hollow, with not less than a one inch radius in the area of the keel fin. This may be checked by use of a disk 2 inches in diameter, fitted to the garboard at a midship section." So... that is what that disk is for.

In the old days they used to carve a very massive (relative to the size of the hull) keel out of solid wood. Then, when the boat was planked, it was the style to have that heavy keel project downward from the canoe shape of the hull. The fin was fitted through a slot in that large piece of wood. That keel piece would be rounded to blend from the hull down to the fin. They actually made a rule that requires this "garboard". It must be at least 1" radius. So instead of trying to carve and shape a large and heavy piece of wood, I'll just filet in a bunch of thickened epoxy and round it over with the disk. It will clean up very easily and will be incredibly strong. If I use the micro-balloons to thicken the epoxy then it shouldn't be too heavy either.

Aloha!

Comments

Post a Comment